I finally managed to get some time to start the reassembling the Eagle Surface Grinder. All the surfaces have now been precision ground. All that is left to do is machine the oil grooves, match the dovetail surfaces, scrape the oil pockets, add the news spindle and ball screws, write some macros for the grbl g-code controller to behave like a surface grinder and the machine is ready for action.

Spindle and Drive Motor

After ordering and installing the new balls as described in a previous post, I am not satisfied with the resulting stiffness and pre-load design of the original spindle. The thinking now is to use a self contained spindle and machine an adapter sleeve. The new spindle axis diameter is 20mm compared to 25mm and the bearings considerably smaller, but for my needs this will be more accurate, even if I can only run 7" wheels. The motor in the base will drive a flat belt transmitting power to a love-joy style coupling in the "head stock" similar to old lathes with addition of the coupling if that makes any sense. Initially I wanted to go with poly V-Belts, but when I saw the very modern Schaublin 102 N-VM-CF still uses crown pulleys and flat belts. I started investigating the advantages of flat belts. The main advantages I could find was, better efficiency, less vibration, and higher speeds. not sure if any of this holds true, but worth a try. Here I will need to design the housing at the back of the spindle housing, which will hold the crown pulley and shaft coupling, for driving the spindle. A direct drive would be more efficient, economical with less vibration, but that would have the motor extend at the back of the spindle housing, similar to the later eagle model shown below, in a small shop not an option.

Knee Oil groves

On the MK3 model the only the table sports oil groove. As discussed in a previous post, I have decided to go with the zig-zag oil grove pattern, it is more time consuming to machine, but should give better results. Below some images on the layout and machining process. The fixed dovetail had a ridge, where it meets the flat surface on the knee, this had me confused for some time as to why I do not get full bearing on the entire flat surface. a few head-scratches later I used a carbide ball nose end mill to machine some clearance in the corner, all this with a portable hand drill. The only straight edge I could find to fit the angled recess was a carpenters knife blade, this worked great!

Ball Screws /Servo/Stepper Motor

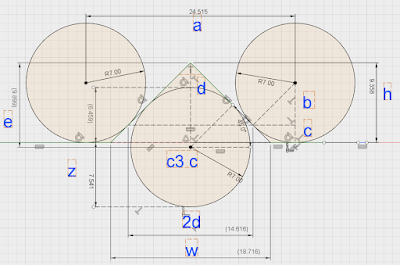

The ACME lead screw needs to be replaced, it has a lead of 10 TPI. I do not feel like cranking the hand wheel so installing a feed motor is a given. Sourcing an ACME 1-1/4" x 10TPI or similar in my part of the world is not feasible. So I opted to go full CNC and use 5mm pitch ball screws. After doing some calculations on THK ball screw specifications with a combined load of 100kg., a 20mm diameter screw will work within load ratings, if a maximum sliding speed of 38mm/s is not exceeded. For a 5mm pitch screw this will give maximum motor speed of 456 rpm. And 8NM motor would be required for https://www.nidec.com/en-EU/technology/calc/torque/ballscrew/ to drive this load.