While rebuilding the Chipmaster, the problem of aligning the carriage bed ways ( bottom slide ) and top slide arise, from what information I can find these have to be at right angles. The bottom slide is worn bananas, so a simple spotting technique, on the bed might cause a lot of headache later to align the cross slide. So I decided to align the tail stock base first, and then use it on the lathe to check which original sufaces on the crosslide are closest to allignment, to be used on the mill setup. I will then cleanup the V groves at the bottom, and do the final spot checking on the lathe beds. So the approach requires three steps.

1) Align the tail-stock on the mill, and touch-up the V slot, and flat surface. Machine one outside surface parallel to the V-Groves. Final fit on the lathe with transfer spotting.

2) Find the best reference surface on the carriage with the fitted tail-stock base as guide. Or bolt an adjustable bar to the back, where the taper attachment usually attaches.

3) Machine the cross-slide base V and flat ways, aligned to identified surface. Fit with transfer bluing.

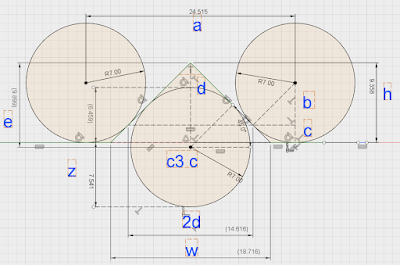

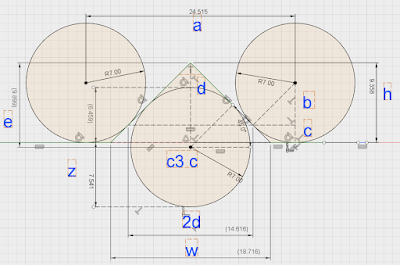

The calculation for the depth of the V slots require similar math to that used for dovetail calculations. I used two 14 mm end mills as gauge pins, the bottom circle is used for measuring the depth, when the base is upside down on the mill, since I want to do the machining in one setup.

Height with14mm gauge pin in V slot, should be z higher than flat surface

On the drawing, the top two 14mm gauge pins are used to measure the_ /\_ ways, the

bottom gauge pin is used to measure height over the flat surface, for a level tail stock base.

map the flat surface to find low points, add z, mill out v until this height is reached

mill down flat surface

measured 38,515 across pins

c1,c2,c3 r 7

a 24,515 measured-2r

b 4,949747468

c 2,050252532 r-b

2d 14,61550506

d 7,307752532

h 9,358005063 c+d

w 18,71601013 2*height

e 9,899494937

c3 center 0,541489873 e-h

z 7,541489873 r+c3 center