In

its first lucky life, my FP2 was used as a sturdy drill press. At some

point it went in for a refurbish and a new paint job to light green, as the previous owner stated more drill press work. Then it

switched hands and got a nice pressure washer spring clean which forced

water below the vertical slide, the little access port at the back

trapped water, and so it started rusting. Which eventually caused

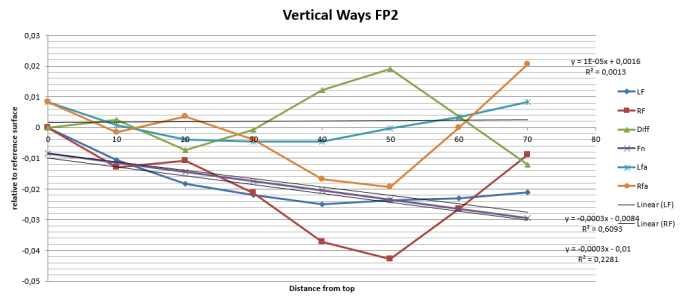

considerable wear on the right way (FR) 0.05mm, compared to the left front

way (FL) worn to about 0.023mm.

When

the transporters dropped it, I decided to take it apart to asses the damage. To my surprise, all oiling points where pumped full of

grease. And I soon discovered the rusty spot. After pondering in the

effort of taking it apart again in future against just fixing it now, I

decided to scrape the ways and get it back to original as close as

possible.

Firstly I measured both ways to a reference surface reference, a granite straight edge. Dan Gelbard has a few interesting videos on YouTube, specifically on machinist meteorology and what he calls duality theory. A true Master in my opinion. In short if two surfaces reference a third unknown surface, the two surfaces can be mapped. So I went and measured and then realized the original machined surface can be used as a reference.

Below

the measured results, which showed a slight inclination in my reference

surface. I later used the original machined surfaces as reference. Below it can be seen that the straightedge inclined at about 0.03mm over the 800mm of vertical column. I did not bother to normalize the measurements.

tbc.

No comments:

Post a Comment